Sofa legs refer to the connectors that connect the sofa to the base, commonly known as “footrests.”

We usually divide sofa legs into three categories: solid wood legs, iron legs, and stainless steel legs.

Among them, zinc alloy furniture legs are more beautiful and are deeply loved by modern young people.

This article will analyze what the production process of furniture sofa legs is like?

From raw materials to finished products, it can be roughly divided into the following 6 parts:

- A. CAD and other industrial software design and drawing

- B. Raw material selection

- C. Metal stamping and bending

- d. Punching processing

- e. Welding and surface treatment

- f. Quality inspection and finished product packaging

Hello everyone, I am dabing who is sharing the world of furniture hardware with you.

Some people say that furniture sofa legs are very simple products without any technical content, just a small “supporting role” among many hardware accessories.

In fact, the role of sofa leg hardware accessories in sofas has always been an indispensable part.

A high-quality hardware accessory is not only strong and durable, but also can add a sense of space to sofas, tables and chairs.

Different curvatures and surfaces also provide homeowners with different visual experiences.

In short, a high-quality hardware accessory has a series of strict requirements in materials, design, packaging, dll..

It also takes into account comfort, convenience, and matching with product style.

A. Design and drawing

In the hardware industry, the first The first step is to make CAD drawings!

It will determine the shape, surface, size and structure of the hardware products.

Mature companies are also equipped with C4D, 3DMAX, MAYA and other modeling and rendering engineers, which can give customers a more obvious visual impact.

Convenient to help customers make modifications and choices to meet market demand.

B. Selection of raw materials

The main raw material of hardware sofa legs is metal material.

Usually made of zinc alloy, aluminum alloy, stainless steel and other materials.

In particular, zinc alloy furniture legs are more popular due to their low melting point, good fluidity, easy welding and plastic processing.

The following are the advantages and disadvantages of various types of furniture legs. We can choose according to the usage scenarios and their respective characteristics.

Solid wood sofa legs:

Basically based on geometry The body is presented in the form of a body, and the surface is painted.

This is a more traditional sofa leg material in China.

Generally, Chinese style or new Chinese style is more suitable.

Good wooden sofa legs are durable, but the price is relatively high.

The disadvantage is that they are easy to wear and tear, and they may grow mold after long-term use, and it is also troublesome to clean and maintain.

Stainless steel sofa legs:

Very textured, practical, and give people a noble and atmospheric feeling.

Generally, high-end sofas will use it, so the cost is also higher, but there is no need to worry about dampness and mold.

Zinc alloy sofa legs:

It has a high density and a relatively smooth and delicate surface. The disadvantage is that the load-bearing capacity is smaller than that of aluminum alloy.

But it is better in appearance and is deeply loved by modern young people.

Plastic sofa legs:

Lightweight, wear-resistant and non-slip, mostly used in low-priced furniture, which is conducive to Protect tile floors.

Namun, plastic has low hardness, and load-bearing capacity is a key factor in considering its quality.

Here, MRH_dabing takes zinc alloy, a mainstream sofa leg, as an example:

Advantages of zinc alloy processing: good casting performance, can produce precision die-castings with complex shapes and uniform wall thickness.

In particular, most of the special-shaped sofa legs are made of zinc alloy, such as the styles in the following pictures:

Of course, when we choose materials, we also need to consider,

- Tensile strength;

- Working environment conditions

- Raw material costs

- Production equipment and other requirements

After all, a product with high cost performance, practical, beautiful and rust-free.

Only in this way can it be deeply loved by the market and help customers gain greater advantages in the local market.

C. Metal stamping and bending forming

At this point, the customer has confirmed the design stage.

The next step is the production process, which involves very complicated content.

Dabing will combine pictures and production videos to give everyone a general understanding!

Stamping stage [The parts after cutting and stamping are the main components of the hardware sofa legs]

Before cutting, metal stamping needs to proofread the sheet and measure its size and thickness.

Generally speaking, ordinary sheets can be processed directly with a punch press, but some complex products still need to go through multiple processes such as sheet metal processing.

In the process of sheet cutting, we need to cut the metal raw materials according to the requirements of the design and drawing.

Professional metal cutting equipment such as laser cutting machine, wire cutting machine, plasma cutting machine, dll.. are required.

Ensure that the cut parts are accurate in size and regular in shape, laying the foundation for subsequent production processes.

Bending and forming stage [key steps for the shape of sofa legs]

Bending and forming is one of the core processes of metal stamping.

There are many ways to bend, such as bending and rolling.

Bending is usually performed using a hydraulic roller punch or a sheet metal bending machine.

When bending, metal stamping workers need to strictly control the bending angle, curvature and bending cracks to ensure good overall performance and quality.

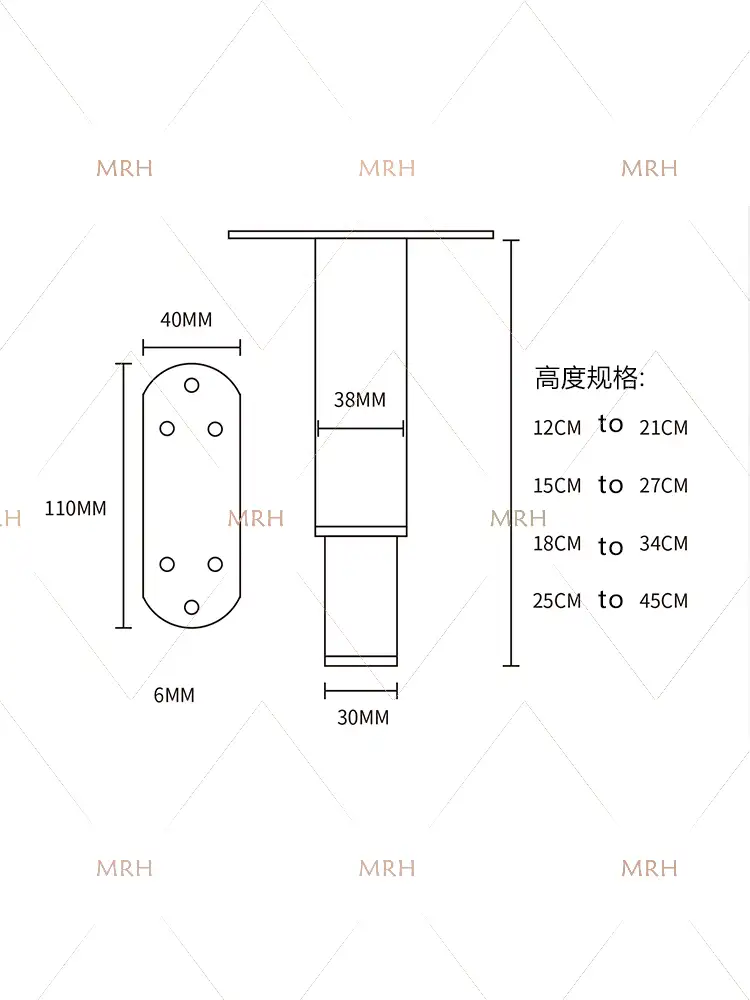

D. Punching and bolt connection stage [Confirmation of the screw hole position for sofa leg installation, generally around 8mm, 10mm or 12mm]

Main processes implemented: trimming, de-ribbing, punching and surface treatment

In this process, the processing master needs to use shearing machines, punching machines and sheet metal processing equipment.

To achieve the accuracy of the screw hole position and smooth surface without hurting the hand.

E. Welding [ensuring tight connection between parts and stable structure] and surface treatment stage [determines the beauty and durability of sofa legs]

Welding: There are many welding methods [such as arc welding, gas welding, argon arc welding, etc.], which can be generally classified into three categories: fusion welding, pressure welding and brazing

Its main function is to ensure tight connection and stable structure between parts.

Metal surface treatment: including spraying, dusting, polishing, electroplating and oxidation.

To enhance the corrosion resistance and hardness of the product, the surface is smooth and beautiful, so as to improve the texture of the sofa legs.

F. Quality inspection [QC] and finished product packaging

Quality inspection and finished product packaging are a very critical line of defense for the survival of enterprises.

Directly affects the cost, customer trust in us and brand moat.

For such an important link, MRH functional hardware manufacturers all adopt segmented sampling and weighing method before they can be packed into boxes.

Finally, our QC randomly selects 10-15 boxes from the whole batch for various tests, including checking the appearance quality, load-bearing test, and throwing test, etc., to ensure that the quality of the product meets the standards.

If you do not have a complete quality inspection process, you can pay attention to the following 6 points:

- Is the environmental protection material policy of the local country in compliance?

- Is the surface of the product smooth, bright and rust-free?

- Are all the accessories required by the customer available?

- Is the packaging bag waterproof and drop-proof ?

- Is the carton thickened?

- Can it withstand long-distance transportation and bad weather?

- Do the outer box correspond to the warehouse number?

- Can the inner box label be scanned and used normally?

If you are interested in MRH’s sofa functional hardware products.

You can contact us:

Pengelola:sulih suara

Surel:dabing362131@gmail.com

Disesuaikan/Grosir:+86-18063147064

Ada apa:+86-13684809607

MRH will give you a satisfactory reply as soon as possible, help you open up the market, and enhance the competitive advantage in the market~V~